Leave Your Message

-

Facebook

-

Whatsapp

-

Whatsapp

In the rapidly evolving landscape of commercial spaces, the demand for hygienic solutions has never been more critical. According to a report by Grand View Research, the global market for wall cladding is projected to reach $45.23 billion by 2025, with PVC hygienic wall cladding emerging as a popular choice due to its exceptional durability and ease of maintenance. With an emphasis on cleanliness and sustainability, businesses in sectors such as healthcare, food service, and education are increasingly turning to PVC hygienic wall cladding for both functionality and aesthetic appeal. This guide will explore the essential steps for installing PVC hygienic wall cladding, providing insights that align with industry standards to ensure a seamless and long-lasting application in your commercial space.

PVC hygienic wall cladding has become increasingly popular in commercial environments, largely due to its myriad benefits. According to a report by the global market research firm, Research and Markets, the PVC wall cladding market is expected to grow at a CAGR of 5.2% from 2022 to 2027, driven by the increasing demand for hygienic and easy-to-maintain surfaces in sectors such as healthcare, food processing, and hospitality. This growth is spurred by the material's resistance to moisture, which significantly reduces the risk of mold and bacterial growth, a critical factor in adhering to health and safety standards.

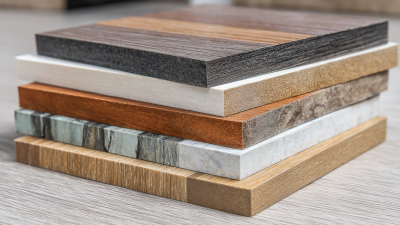

Another significant advantage of PVC hygienic wall cladding is its ease of installation and maintenance. Studies show that businesses can reduce wall maintenance costs by up to 50% when opting for PVC over traditional wall materials. The non-porous surface of PVC makes it easy to clean and maintain, leading to lower overall cleaning costs and enhanced durability. Furthermore, its aesthetic versatility and availability in various colors and textures allow businesses to create a welcoming atmosphere while ensuring compliance with hygiene regulations. This blend of functionality and design makes PVC cladding an essential choice for modern commercial spaces.

| Key Benefits | Description | Applications | Maintenance |

|---|---|---|---|

| Hygienic | Prevents the growth of bacteria and reduces contamination risks. | Hospitals, laboratories | Easy to clean with standard cleaning agents. |

| Durability | Resistant to impacts, scratches, and moisture. | Commercial kitchens, food processing areas | Minimal maintenance required; lasts for years. |

| Aesthetic Appeal | Available in a wide range of colors and finishes to enhance the space. | Restaurants, retail spaces | Regular dusting and periodic washes needed to maintain appearance. |

| Cost-Effective | Lower installation costs compared to traditional wall materials. | Warehouses, storage facilities | Requires less frequent replacement, saving costs over time. |

| Easy Installation | Quick to install with minimal disruption to the operation. | Schools, offices | Installation does not require specialized tools. |

When it comes to installing PVC hygienic wall cladding in commercial spaces, having the right tools and materials is crucial for ensuring a seamless finish and long-lasting durability. Key tools include a utility knife for precise cutting, a straight edge for accurate measurements, and a trowel or adhesive spreader for applying the adhesive. According to a recent industry report, proper tool selection can reduce installation time by up to 30%, making efficiency a top priority for contractors working in the competitive commercial sector.

In addition to tools, quality materials play a significant role in the installation process. High-grade PVC panels not only offer superior hygiene and easy maintenance but also can withstand the rigorous demands of environments such as hospitals, kitchens, and laboratories. Data from the International Association of Plumbing and Mechanical Officials highlights that installations using reinforced PVC cladding are less likely to suffer from mold growth, promoting a healthier environment. Investing in the right materials upfront can lead to lower long-term maintenance costs and enhanced aesthetic appeal, thereby increasing customer satisfaction and repeat business for commercial establishments.

Installing PVC hygienic wall cladding in commercial spaces can significantly enhance the cleanliness and aesthetic appeal of any environment. Before starting the installation process, proper preparation of the space is crucial. First, ensure that the walls are clean, dry, and free of any existing fixtures that might interfere with the cladding. This step not only guarantees a smooth application but also ensures that the cladding adheres effectively for long-lasting results.

Tips for Preparation:

When it comes to installing PVC hygienic wall cladding in commercial spaces, achieving a professional finish is paramount. According to a report by the International Journal of Hygiene and Environmental Health, surfaces that are easy to clean and maintain can lead to a 40% reduction in bacterial contamination, making proper installation essential for health-conscious environments. Expert tips emphasize the importance of surface preparation; ensuring that walls are clean, dry, and structurally sound can significantly enhance the adhesion of the cladding.

Furthermore, utilizing the right tools and materials is crucial for a seamless finish. Industry standards recommend using high-quality adhesives specifically designed for PVC, as they provide superior bonding strength and flexibility. According to a study from the American Society for Testing and Materials (ASTM), improperly applied adhesive can compromise up to 30% of the wall cladding's lifespan. Additionally, ensuring that joints fit tightly and are properly sealed can further enhance the hygienic properties of the installation. Adopting these expert techniques not only contributes to the aesthetic appeal but also to the longevity and cleanliness of the space.

When installing PVC hygienic wall cladding in commercial spaces, avoiding common pitfalls is crucial to ensuring a successful project. One frequent mistake is inadequate surface preparation. Before installation, it's essential to clean and smooth the walls thoroughly. Failing to do so can lead to poor adhesion, resulting in potential lifting or peeling over time. Additionally, neglecting to check for moisture issues can compromise the cladding's integrity, making it vital to assess the wall condition and perform necessary repairs prior to installation.

Another common error is misalignment during the installation process. If the panels are not aligned correctly, it can affect the overall aesthetics and functionality of the space. Taking the time to measure and mark guidelines will help ensure that the panels fit properly and create a seamless appearance. Furthermore, using the wrong adhesives can also derail the project; it’s essential to use adhesives specifically designed for PVC cladding to guarantee durability against the unique challenges of commercial environments. Paying attention to these details can lead to a more efficient and visually pleasing installation.