Leave Your Message

-

Facebook

-

Whatsapp

-

Whatsapp

In recent years, the demand for high-quality Plastic Cladding Sheets has surged across various sectors, driven by the need for durable, lightweight, and cost-effective building materials. According to a market research report by Smithers Pira, the plastic cladding market is expected to reach $7.3 billion by 2025, reflecting a growing trend towards synthetic materials in construction and design. These sheets offer a versatile solution for both aesthetic and functional applications, making them an attractive choice for homeowners and contractors alike. However, with a myriad of options available, selecting the right Plastic Cladding Sheets for your project can be a daunting task. This blog aims to equip you with ten essential tips to navigate this selection process effectively, ensuring you make an informed choice that meets your project's specific needs and enhances its overall value.

Plastic cladding sheets have become increasingly popular across various industries due to their versatility and durability. They offer numerous benefits, making them an ideal choice for construction, signage, and even interior design. According to a report by Smithers Pira, the global market for plastic cladding is expected to reach $2.3 billion by 2025, driven by growing demand for lightweight and weather-resistant materials.

The advantages of plastic cladding sheets include excellent weather resistance, low maintenance requirements, and their ability to reduce energy costs through insulation.

Plastic cladding sheets have become increasingly popular across various industries due to their versatility and durability. They offer numerous benefits, making them an ideal choice for construction, signage, and even interior design. According to a report by Smithers Pira, the global market for plastic cladding is expected to reach $2.3 billion by 2025, driven by growing demand for lightweight and weather-resistant materials.

The advantages of plastic cladding sheets include excellent weather resistance, low maintenance requirements, and their ability to reduce energy costs through insulation.

When selecting plastic cladding sheets for your project, consider the specific application. It’s critical to choose sheets that are UV resistant if they will be exposed to sunlight. Additionally, look for products with strong impact resistance, especially for high-traffic areas where durability is paramount. Another tip is to evaluate the thermal properties of the sheets; some materials can significantly enhance energy efficiency by reflecting heat. Remember, the right choice can not only add aesthetic appeal but also provide long-term cost savings.

Ultimately, your selection should align with the intended use of the cladding sheets. For instance, in humid environments, opt for sheets with anti-microbial properties to prevent mold and mildew growth. As the market evolves, these materials continue to gain traction, providing innovative solutions for modern architectural needs.

When selecting plastic cladding sheets for your project, it's crucial to consider several key factors that can significantly impact both aesthetics and functionality. First and foremost, examine the material's durability. High-quality plastic sheets should withstand harsh weather conditions, resist fading, and maintain their integrity over time. It's advisable to choose sheets that have been UV stabilized to ensure long-lasting performance.

Another essential tip is to evaluate the thickness of the sheets. Thicker cladding provides better insulation and impact resistance, making it suitable for high-traffic areas or environments prone to harsh conditions. Additionally, think about the design and texture of the cladding. Different finishes and colors can enhance the visual appeal of your project, so select options that complement your overall design theme.

Lastly, consider the installation and maintenance aspects of the cladding sheets. Ease of installation can save both time and costs, so look for lightweight options that can be handled easily. Furthermore, choose cladding that requires minimal maintenance, allowing you to enjoy your space without constant upkeep. By focusing on these key factors, you can confidently select the right plastic cladding sheets for your project.

| Tip No. | Factor to Consider | Description |

|---|---|---|

| 1 | Material Type | Choose between PVC, Polycarbonate, or Acrylic based on your project's needs. |

| 2 | Thickness | Select appropriate thickness for durability and insulation. |

| 3 | Color | Consider color options to match with your building aesthetics. |

| 4 | UV Resistance | Ensure the sheets offer UV resistance for longevity. |

| 5 | Fire Rating | Check the fire safety ratings to comply with building regulations. |

| 6 | Finish | Decide on a matte or glossy finish based on the desired look. |

| 7 | Cost | Evaluate your budget and compare prices for different materials. |

| 8 | Installation | Consider ease of installation and whether to hire a professional. |

| 9 | Maintenance | Assess the maintenance requirements for the chosen cladding. |

| 10 | Warranty | Check the warranty terms for longevity and protection. |

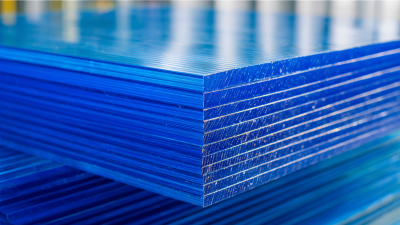

When selecting plastic cladding sheets for your project, understanding the different types of plastic materials and their properties is essential.

Polyvinyl Chloride (PVC) is one of the most commonly used plastics in cladding. Durable and cost-effective, PVC boasts excellent weather resistance and can last up to 30 years if maintained properly.

According to a study by the Plastics Industry Association, PVC cladding accounts for approximately 40% of the plastic building materials market, highlighting its popularity in construction projects.

Another notable material is Polycarbonate, known for its high impact resistance and clarity. It allows for greater design flexibility, with options ranging from translucent sheets that permit light while maintaining privacy to solid panels that offer durability.

Research by the American Chemistry Council indicates that the use of polycarbonate in construction has grown by 15% annually, driven by the increasing demand for lightweight and energy-efficient materials.

Understanding the properties of these materials will help you choose the right plastic cladding sheets that meet the specific needs of your project, ensuring both functionality and aesthetic appeal.

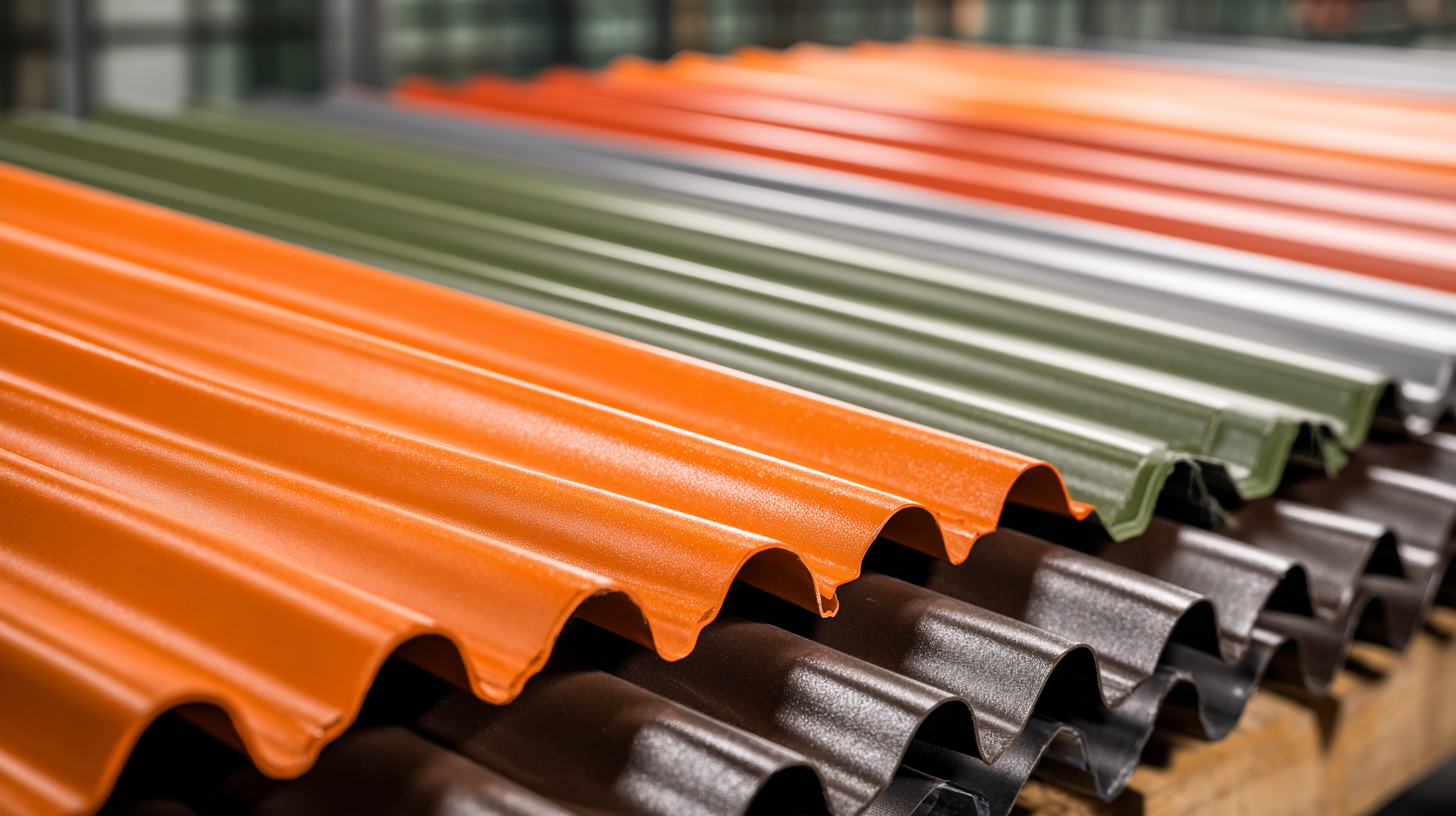

When it comes to selecting plastic cladding sheets for your project, the aesthetic finish plays a crucial role in determining the overall appeal of your space. The variety of finishes available can enhance the visual impact of your design, ranging from matte to glossy options. Matte finishes provide a subtle, understated elegance that can complement contemporary designs, while glossy finishes offer a sleek, modern look that reflects light beautifully. It's essential to consider the surrounding architecture and the atmosphere you wish to create when choosing between these aesthetic options.

Color is another vital aspect of the aesthetic appeal of plastic cladding. Different colors can evoke distinct emotions and set the tone for your project. For instance, cooler colors like blue and green can create a calming, refreshing environment, while warmer hues like red and orange can evoke energy and vibrancy. Additionally, the choice of texture can add depth and dimension to your cladding. Textured finishes may resemble natural materials, providing a more organic feel, whereas smooth finishes can convey a sense of cleanliness and sophistication. Balancing these aesthetic options is key to achieving a cohesive and visually striking result in your design.

When embarking on a plastic cladding project, cost-effectiveness is paramount. According to a 2022 report by Smith & Associates, the average cost of plastic cladding materials can range from $2 to $5 per square foot, depending on the type and thickness of the sheet chosen. Budgeting for your project requires a careful analysis of these costs, alongside any additional expenses such as insulation or installation techniques. By selecting high-quality, durable plastic sheets, you can mitigate long-term maintenance costs often associated with lower-priced materials, which may require replacement or repairs sooner than expected.

Furthermore, the lifecycle cost analysis indicates that investing in premium plastic cladding can yield substantial savings over time. A study by the Plastics Industry Association highlighted that buildings clad with high-grade plastic materials could save up to 30% in energy costs due to improved insulation properties. This creates a compelling argument for not only considering initial material costs but also the overall financial benefits of selecting the right plastic cladding. Balancing quality with budget ensures that your project is not only economically viable but also sustainable and efficient in the long run.