Leave Your Message

-

Facebook

-

Whatsapp

-

Whatsapp

When embarking on a construction or renovation project, one crucial decision revolves around the materials you choose, particularly when it comes to enhancing both the aesthetic and functional aspects of your structure. Plastic Cladding Sheets have become increasingly popular due to their versatility, durability, and ease of maintenance. In this ultimate guide, we will explore the various types of plastic cladding sheets available, their unique features, and the key factors to consider when selecting the right option for your specific project needs. Whether you're looking to improve insulation, weather resistance, or simply looking for a modern look, understanding the choices and applications of plastic cladding sheets is essential. Join us as we dive into the world of plastic cladding and provide you with expert insights to help you make an informed decision.

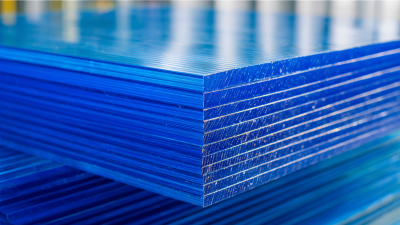

When embarking on a project that involves plastic cladding sheets, it's essential to understand the various types available to make an informed choice. Plastic cladding comes in a multitude of materials, including PVC, polycarbonate, and acrylic, each with its own unique properties. PVC sheets are known for their affordability and versatility, making them ideal for residential applications. On the other hand, polycarbonate offers superior impact resistance, making it suitable for commercial and industrial settings where durability is crucial.

Tip: When selecting the right type of plastic cladding, consider the specific needs of your project. For example, if you require transparency for natural light, polycarbonate sheets may be the better option. Additionally, think about long-term exposure to weather conditions—some materials are more UV resistant than others, which can affect their longevity.

Another critical factor to consider is the available finish and color options. Some plastic cladding sheets come textured or patterned, helping to enhance aesthetic appeal. For projects where aesthetics are just as important as functionality, choose a cladding sheet that complements your design while fulfilling performance requirements.

Tip: Always request samples before making a bulk purchase. This step allows you to assess the sheet's appearance, weight, and texture, helping ensure that the final product aligns with your project's vision.

| Type of Plastic Cladding | Material | Typical Thickness (mm) | Fire Rating | UV Resistance | Color Options |

|---|---|---|---|---|---|

| Polycarbonate Sheets | Polycarbonate | 3-10 | B1 | High | Clear, Opal, Bronze |

| PVC Sheets | PVC | 2-6 | B2 | Moderate | White, Grey, Blue |

| Acrylic Sheets | Acrylic | 3-8 | A | Excellent | Clear, Frosted, Colored |

| Polypropylene Sheets | Polypropylene | 2-5 | B2 | High | White, Black |

When tackling a project that involves plastic cladding sheets, several key factors should guide your selection process. First and foremost, consider the climate and environmental conditions of the installation site. Different plastic materials, such as PVC, polyethylene, or polypropylene, offer varying levels of durability and resistance to UV rays, moisture, and temperature fluctuations. Understanding these characteristics is crucial in ensuring the cladding will maintain its integrity over time.

When tackling a project that involves plastic cladding sheets, several key factors should guide your selection process. First and foremost, consider the climate and environmental conditions of the installation site. Different plastic materials, such as PVC, polyethylene, or polypropylene, offer varying levels of durability and resistance to UV rays, moisture, and temperature fluctuations. Understanding these characteristics is crucial in ensuring the cladding will maintain its integrity over time.

Another important aspect to evaluate is the aesthetic appeal and finish of the cladding sheets. The appearance of the sheets can significantly influence the overall look of your project. Options range from smooth finishes that offer a modern appeal to textured surfaces that can mimic natural materials. Moreover, consider whether you need custom colors or designs that blend seamlessly with your existing architecture.

Lastly, do not overlook the installation and maintenance requirements of the cladding sheets. Some materials may require specialized tools or skills for installation, while others offer ease of use for DIY projects. Additionally, consider the long-term maintenance involved, as certain plastics may be more resistant to stains and easier to clean than others, ultimately affecting the life and look of your cladding over time.

When choosing plastic cladding sheets for your project, weighing the cost against quality is crucial. High-quality plastic cladding can provide durability and weather resistance, ensuring a long-lasting finish for your structures. However, cheaper options may allure you with lower prices, yet they could lead to increased maintenance costs and potential replacements in the future. Always consider the materials' specifications and warranties before making a decision.

**Tips**: Always check supplier reviews and product certifications to ensure quality. Additionally, consider bulk purchasing to reduce costs, but ensure you’re not compromising on the quality of material. Consulting with professionals in the field can also provide insights into the best options based on your specific needs.

The advancements in materials like plastic are reflected in various sectors, as seen in the need for innovation in manufacturing lightweight solutions. Just as the military explores advanced materials for ammunition, your project could also benefit from the latest developments in plastic technology. Make sure to keep an eye out for industry trends that prioritize both cost-effectiveness and quality.

When selecting plastic cladding sheets for your project, ensuring their longevity and durability is paramount. Recent studies indicate that advancements in sustainable building materials have led to the development of plastic cladding options that offer not just aesthetic appeal but also improved performance metrics. For instance, high-quality plastic sheets now incorporate innovative production technologies that enhance resistance to UV degradation and environmental wear, extending their lifespan significantly—some estimates suggest up to 50% longer than traditional materials.

In addition to selecting materials with technological advancements, proper installation and maintenance are critical. Reports show that poorly installed cladding can lead to moisture penetration and structural damage, which diminishes the durability of even the best materials. Furthermore, employing products that feature high recyclability rates can contribute to sustainability goals while ensuring that your cladding retains its functionality over time. As the building industry pivots towards greener practices, embracing these trends not only addresses environmental concerns but also aligns with the increasing demand from consumers for durable, eco-friendly options.

When it comes to selecting the right plastic cladding sheets for your project, the brand and product quality play a crucial role in achieving the desired aesthetic and functional outcomes. Among the top brands in the market, companies like Celuka, PVC Cladding, and Polycarbonate offer a range of solutions known for their durability and versatility. Celuka cladding is particularly favored for its high-density foam structure, making it resistant to impacts and weathering, which is ideal for outdoor applications.

In addition to brand reputation, specific product features should influence your choice. For instance, PVC cladding products are lightweight and easy to install, making them popular for DIY projects. Meanwhile, polycarbonate sheets offer excellent thermal properties and UV resistance, making them suitable for both residential and commercial buildings. By focusing on reputable brands and understanding the unique features of their products, you can ensure that your plastic cladding sheets not only enhance the visual appeal of your project but also stand the test of time.