Leave Your Message

-

Facebook

-

Whatsapp

-

Whatsapp

Plastic wall cladding has gained significant traction in the construction and interior design industries due to its durability, versatility, and cost-effectiveness. According to a report by Smithers Pira, the global market for plastic wall cladding is projected to reach $12 billion by 2025, indicating a growing preference for these solutions in both residential and commercial applications. However, despite its widespread use, several issues have been identified that can compromise performance and aesthetics, such as material degradation, thermal expansion, and environmental impact.

As stakeholders seek alternatives to traditional plastic wall cladding, it is essential to explore innovative solutions that address these challenges, while also meeting the increasing demand for sustainable and efficient building materials. This blog will delve into the various alternatives available, examining their benefits and potential drawbacks in comparison to conventional plastic wall cladding options.

Plastic wall cladding has gained popularity in various construction projects due to its lightweight nature and resistance to moisture. However, despite its advantages, several common challenges can hinder its effective application. According to a report by Transparency Market Research, the global plastic cladding market is expected to reach $9.4 billion by 2027, but issues such as discoloration, temperature sensitivity, and durability remain significant concerns for industry professionals.

One prevalent challenge with plastic wall cladding is its tendency to fade or discolor when exposed to UV radiation. A study by the American Society for Testing and Materials (ASTM) revealed that some plastic materials can lose more than 20% of their color within the first three years of installation. Moreover, temperature fluctuations can lead to thermal expansion and contraction, causing gaps and compromising the integrity of the cladding. A report from the National Institute of Building Sciences emphasizes that improper installation due to these factors can lead to an estimated 15% increase in maintenance costs over the lifespan of the material.

Furthermore, the sustainability of plastic wall cladding has drawn scrutiny. As the industry moves toward greener building practices, the environmental impact of plastic waste poses a challenge. The Plastics Europe Industry Association indicates that approximately 30% of plastic products are sourced from recycled materials, highlighting the need for improved recycling and life-cycle strategies in cladding solutions. These issues underscore the importance of careful selection and installation of plastic wall cladding to mitigate potential setbacks in construction projects.

The environmental impact of plastic wall cladding solutions has become a significant concern in the construction industry. Although these materials are often chosen for their durability and aesthetic appeal, their production and disposal pose serious ecological challenges. The manufacturing process of plastic cladding typically involves fossil fuels, leading to high carbon emissions. Additionally, the use of non-renewable resources contributes to the depletion of natural materials, raising questions about sustainability.

Moreover, the long-term effects of plastic waste in landfills and oceans can no longer be ignored. Plastic wall cladding, when discarded, may take hundreds of years to decompose, contributing to the global plastic pollution crisis. Although some manufacturers are exploring recycling options and bioplastics, the effectiveness and availability of these solutions remain limited. As the push for greener building practices grows, it is crucial for architects and constructors to consider the environmental footprint of their materials and seek more sustainable alternatives that minimize harm to our planet.

Plastic wall cladding offers a versatile and cost-effective solution for various building applications, but it comes with its own set of challenges. To mitigate common issues such as fading, warping, and peeling, implementing effective maintenance strategies is essential. Regular inspections are a critical first step in identifying early signs of wear and tear. Property owners should inspect the cladding surface at least once a season and look for signs of discoloration or physical damage. Prompt attention to these issues can prevent them from escalating and becoming more costly repairs.

In addition to inspections, establishing a cleaning regimen can greatly extend the lifespan of plastic wall cladding. Using gentle cleaners and avoiding abrasive materials will help maintain the visual appeal of the cladding without causing damage. Furthermore, applying a protective sealant every few years can enhance the cladding's resistance to UV rays and moisture infiltration, addressing some of the primary problems associated with degradation. By combining routine inspections with proactive cleaning and protective measures, property owners can ensure their plastic wall cladding remains attractive and functional for years to come.

| Issue | Description | Maintenance Strategy | Frequency |

|---|---|---|---|

| UV Degradation | Exposure to sunlight can lead to discoloration and brittleness. | Regular inspection and application of UV-resistant coatings. | Annually |

| Mold and Mildew | Moist environments promote mold growth on cladding surfaces. | Cleaning with mold-inhibiting solutions and ensuring proper drainage. | Biannually |

| Cracking | Temperature fluctuations can cause the material to expand and contract. | Install expansion joints and monitor for any visible cracks. | After severe weather changes |

| Scratching | Physical damage due to impacts or abrasions. | Use protective barriers and regularly check for signs of wear. | Quarterly |

| Color Fading | Prolonged exposure to elements can fade colors. | Reapply color coatings as necessary. | Every 3-5 years |

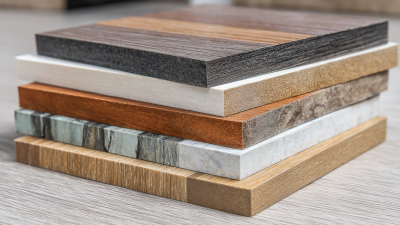

The growing concerns surrounding traditional plastic wall cladding solutions have led to a surge in innovative alternatives that align more closely with sustainable practices. One prominent solution gaining traction is wood-plastic composites (WPC), which combine the durability of plastic with the aesthetic appeal of wood. According to industry reports, the global WPC market is projected to reach a staggering value of $6400.5 million by 2025, and it is expected to expand to $12941.7 million by 2033, showcasing a compound annual growth rate (CAGR) of 9.2%. This emerging market reflects a significant shift toward eco-friendly materials that meet both functional and aesthetic needs.

In addition to WPC, the single-wall corrugated cardboard market is also witnessing considerable expansion. With applications spanning various industries, including food and beverage and electronics, this market is characterized by diverse thicknesses and product types. The surge in demand for sustainable packaging solutions underscores a broader trend towards innovative material alternatives. Furthermore, the biobased polypropylene market is anticipated to grow from $255.8 million in 2024 to an impressive $3.8241 billion by 2032, with an astonishing CAGR of 39.9%. These figures not only illustrate the rapid advancement of alternative materials but also highlight the increasing importance of sustainable practices in the development of wall cladding solutions.

When considering plastic wall cladding solutions, effective installation techniques are crucial to avoid common issues that can arise during and after the application. A primary concern is ensuring proper air-sealing and moisture management. If air leakage is not adequately addressed, it can lead to trapped moisture, resulting in mold growth and material degradation. To mitigate this, builders should implement robust sealing strategies, particularly around windows and joints, where airflow is most likely to occur.

Another significant aspect is the correlation between insulation and cladding. Insulation plays a vital role in maintaining the integrity of the cladding system. Uninsulated or poorly insulated walls can exacerbate heat loss—potentially up to 25% through inadequately insulated areas—which can impact overall energy efficiency. Therefore, incorporating solid wall insulation alongside plastic cladding not only enhances thermal performance but also reduces the risk of thermal bridging and subsequent condensation issues.

Overall, a meticulous approach to both insulation and cladding installation will ensure a durable and efficient exterior solution.